- Background -

All yogurt producers must maintain a specific temperature range during incubation to ensure the yogurt culture remains active and effective. The ideal refrigeration temperature for yogurt is between 36-40°F (2-4°C). Within this range, bacterial growth significantly slows down, helping to keep the yogurt fresh and safe for consumption over an extended period.

- Challenges -

Although yogurt production machines come with built-in thermometers, these devices only measure the machine’s temperature, not the yogurt’s. Real-time monitoring of yogurt temperature, which should stay between 36 to 40 °F (2-4°C), is unavailable. Regulatory agencies require food producers to log temperature data to ensure the safety of products before they enter the market.

This situation presents several challenges:

Lack of Early Warning Systems: Without real-time monitoring, there’s no way to promptly detect and address situations where the yogurt’s temperature exceeds 41°F.

Food Safety Risks: If the yogurt’s temperature rises above 41°F and then returns to the normal range, it may have already spoiled, yet this change goes unnoticed by staff.

Labor Costs: Staff must manually check the yogurt’s temperature with handheld thermometers at regular intervals, a process that requires significant human resource investment due to the large number of machines.

- Solution -

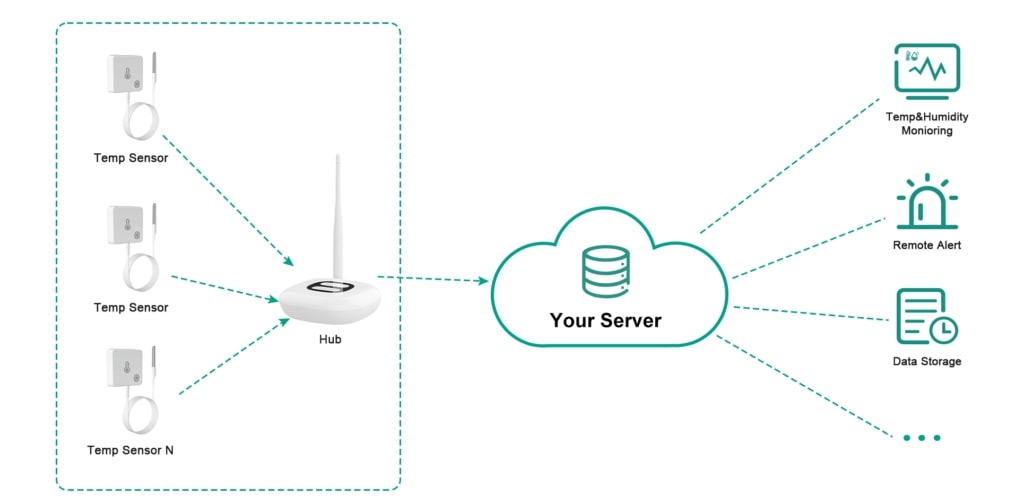

The solution to these challenges is a Real-Time Temperature Monitoring System, which supports:

Real-time temperature monitoring

Remote Alerts: Sends alerts (notifications, emails) to the staff on duty or the facility manager.

Automatic temperature data logging

- Benefit -

The introduction of a Real-Time Temperature Monitoring System significantly enhances food safety and operational efficiency in yogurt production. This system not only minimizes the risk of spoiling by maintaining optimal temperatures but also streamlines compliance with health regulations through automated temperature logging.

By reducing the need for manual checks, it also lowers labor costs and frees up staff to focus on other productive tasks, thereby improving overall workflow and productivity.

- Conclusion -

Getting a Real-Time Temperature Monitoring System on board is a smart step for keeping our yogurt quality and safety top of the line. It tackles the big issues head-on, with round-the-clock monitoring, quick alerts if temps go wonky, and an easy-breezy way to meet health standards. It’s a forward-thinking move that not only looks out for our customers’ health but also makes our operations smoother and more cost-effective.