Reliable Freezer Temperature Monitoring in Unreliable Conditions: MOCREO’s Impact on LOMWRU’s Freezer Management

Client: Laos-Oxford-Mahosot Hospital-Welcome Trust Research Unit (LOMWRU)

Contact: Dr. Matthew Robinson, Head of Molecular Bacteriology

Location: Vientiane, Lao PDR

Industry: Academic Research and Diagnostics Laboratory

Core Focus: Infectious Disease Research, Diagnostics, and Laboratory Training

LOMWRU is a leading research institution focused on infectious disease diagnostics and training in Laos. With a large inventory of critical research materials that must be stored under strict temperature controls, they faced a big challenge and needed freezer temperature monitoring solutions after moving into a new building.

- Challenges in Freezer Temperature Monitoring -

LOMWRU had to deal with an unreliable power supply, especially during the wet season. Their research materials were stored in:

- 18 ultra-low freezers (-80°C)

- 20 low-temperature freezers (-20°C)

- 10 fridges (+4°C)

Power outages and equipment malfunctions made it hard to protect these vital samples. For 20 years, the team manually checked temperatures twice a day, which left room for error and risk. Without real-time monitoring, freezer breakdowns or power losses often went unnoticed until it was too late.

- Freezer Monitoring Needs in a Research Environment -

To keep their research materials safe, LOMWRU needed a cost-effective monitoring system that could provide:

- Remote, real-time temperature monitoring for all freezers and fridges.

- High accuracy within +/- 1°C to ensure reliable data.

- Custom alerts to notify staff during power outages or equipment malfunctions.

- Long-term operational capability without costly fees.

- The ability to add sensors and easily switch them as the equipment is moved.

- A trial option to test the system before committing to a large purchase.

- MOCREO’s Real-Time Freezer Monitoring Solution -

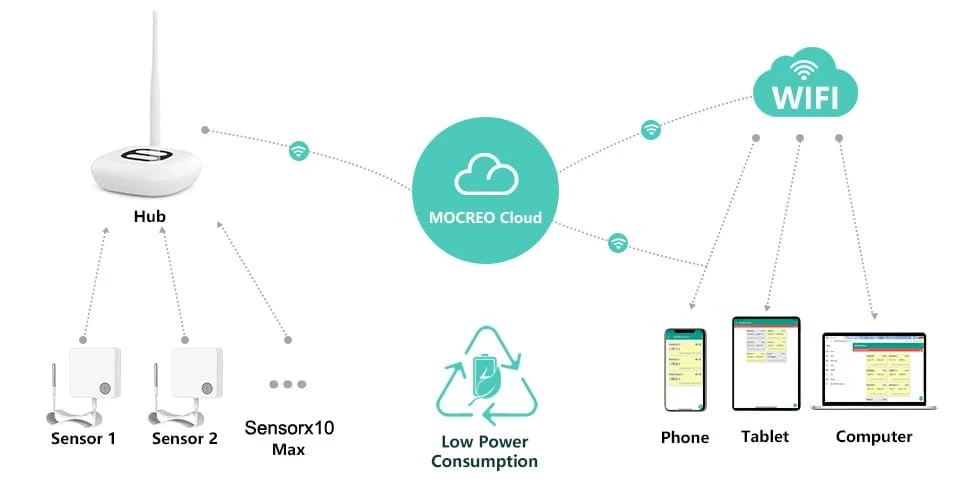

After some research, LOMWRU discovered MOCREO’s real-time monitoring system, which perfectly fit their requirements. The system allowed them to monitor temperatures online through an app and receive immediate alerts if conditions went outside the safe range. This was exactly what they needed to keep their research materials safe.

Initial Purchase: A Trial Phase to Test MOCREO's Freezer Sensors

To make sure MOCREO would meet their needs, LOMWRU started with a small trial, buying the following:

- 2 MOCREO ST10 Ultra Low Temperature Sensors

- 1 IoT Hub

During the trial, MOCREO’s system performed well, offering accurate (+/- 1°C) data for their ultra-low freezers and sending alerts when conditions changed. The system was easy to use and could be managed remotely through a smartphone or computer, making it an excellent fit for their operations.

Post-Trial Expansion

After a successful two-week trial, LOMWRU decided to expand its temperature monitoring system by purchasing:

- 20 additional ST10 Ultra Low Temperature Sensors

- 5 more IoT Hubs

This allowed them to monitor all of their freezers and fridges across the entire facility with MOCREO freezer sensors.

- Key Features of the MOCREO System -

Here are some of the main reasons why MOCREO’s freezer management system was such a good fit for LOMWRU:

1. Real-Time Monitoring

LOMWRU can now monitor the temperature of their equipment from anywhere using the MOCREO app on their smartphones or computers.

2. Accurate Measurements

The ST10 sensor provides precise temperature readings within +/- 1°C, meeting the accuracy requirements for sensitive research materials.

3. Custom Alerts

MOCREO’s system sends email alerts when temperatures go outside of preset limits so the team can respond quickly to prevent freezer failures.

4. Cost-Effective Solution

Compared to other monitoring systems, MOCREO’s solution was affordable, which was a big advantage for LOMWRU as a research institution with limited funding.

5. Scalability

MOCREO’s system is easy to expand. LOMWRU can add more sensors and hubs as needed to cover new equipment or locations without any hassle.

- Results and Benefits -

By using MOCREO’s real-time monitoring system, LOMWRU achieved several key improvements:

1. Reduced Risk of Sample Loss: The new system detects temperature changes and equipment failures in real time, reducing the risk of losing valuable research materials due to freezer malfunctions.

2. Increased Efficiency: With MOCREO’s system in place, LOMWRU no longer has to rely on manual monitoring. This saves time and ensures that their freezers and fridges are being watched 24/7.

3. Long-Term Cost Savings: The trial phase showed that MOCREO’s system was both reliable and affordable, allowing LOMWRU to save money over the long term compared to more expensive options.

4. Seamless Expansion: MOCREO’s flexible design allowed LOMWRU to easily expand its monitoring system as needed without complicated installations or additional expenses.

- Conclusion -

MOCREO’s freezer temperature monitoring solution gave LOMWRU the reliable, cost-effective, real-time monitoring solution they needed to manage their freezers in challenging conditions. The success of the initial trial led to a full-scale deployment, helping LOMWRU protect its critical research materials, improve operational efficiency, and reduce risks related to power outages and freezer failures.

By choosing MOCREO, LOMWRU can now focus on what they do best—leading research on infectious diseases—while trusting that their essential equipment is being monitored in real-time.

Do you want to protect your lab’s critical research materials? Start your trial with MOCREO’s real-time monitoring solution and ensure 24/7 freezer protection. Contact us today for a free demo and see how easy it is to safeguard your valuable samples.