- Background -

HACCP (Hazard Analysis and Critical Control Points) regulations are critical to ensuring food safety. They provide a systematic approach to identifying and controlling hazardous substances during food production and processing. In this blog, we’ll explore how sensor technology can help improve compliance with HACCP regulations.

- Overview of HACCP Regulations -

HACCP regulations are a set of guidelines that food manufacturers and processors follow to ensure food safety. The core of HACCP regulations is the identification of critical control points (CCPs) in the food production process where hazards can be controlled.

Businesses that wish to manage food safety by implementing monitoring systems based on HACCP principles must:

Conduct a comprehensive assessment of each stage of the food production process to identify potential foodborne hazards and establish control measures.

Identify critical control points (CCPs) where hazards can be prevented, eliminated, or reduced to acceptable levels, and ensure their accuracy and completeness.

Establish critical limits for CCPs, specifying the maximum and/or minimum levels to which parameters must be controlled.

Continuously monitor CCPs through effective procedures to detect deviations or loss of control, ensuring that monitoring equipment is accurately calibrated.

Develop corrective action plans for addressing deviations from established critical limits (Step 3).

Establish verification procedures to confirm that the system is operating as planned.

Maintain accurate and comprehensive records and documentation to support the management of the HACCP system.

- Challenges -

Manual execution of HACCP regulations can be both time-consuming and ineffective as well as be tend to cause the potential manual errors. This is where sensor technology comes in, providing automated and efficient monitoring for executing the food safety measures well. By utilizing sensors, organizations can improve their HACCP implementation processes, ensuring greater accuracy in identifying potential hazards, and making the timely actions.

- Solution -

Sensor Technology Overview

Sensor technology includes various types of sensors such as temperature sensors, humidity sensors, etc. These sensors are beneficial for food safety by monitoring the storage conditions and ensure compliance with HACCP regulations. They can help identify potential hazards that could otherwise go undetected.

Benefits in HACCP Regulations

Sensor technology can help increase compliance with the HACCP regulations by monitoring and detect hazards.

With such technology, it can monitor the temperature of food products during transportation and storage, thus reducing the need for periodic manual checks. This can lead to cost savings and greater efficiency.

Additionally, sensor detects a abnormal fluctuation and an immediately alert operators to take corrective action. This can prevent food spoilage or contamination and reduce the risk of foodborne illness.

What’s more, sensor technology can support decision-making by providing data and insights for performance analysis and optimization. For example, sensors can collect data on the production process, such as the temperature and humidity levels during baking. This data can be used to optimize the process to produce higher quality and safer products.

Finally, sensor technology can support regulatory compliance by providing data on food safety practices and conditions. This data can be used to demonstrate compliance with food safety standards and regulations.

- Application -

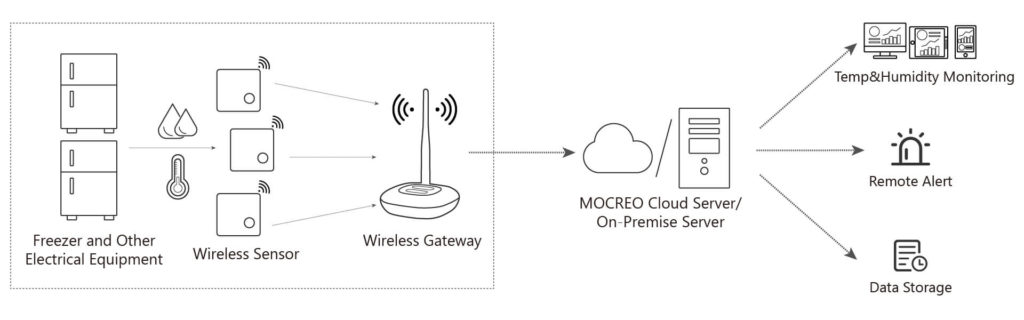

Base on the sensor technology, MOCREO keeps an eye on your valuable assets, peace of mind. Our sensors can be widely used in restaurants, pharmacies, hospitals, greenhouse, etc. It does well in 24/7 real-time environmental monitoring and automatic data recording. You can check out the environmental conditions anywhere at any moment on your devices.

In addition, you can preset the the threshold value and when something abnormal appears, the MOCREO sensor will immediately send out the signal to MOCREO IoT Cloud through wireless gateway. Finally, you would receive the alert notification on your phone, tablet or computer to take the responding action.

- Future -

The application of sensor technology in HACCP regulations plays a crucial role in ensuring food safety. Real-time monitoring and automatic recording improve accuracy, reduce error rates, and promote quick response to potential hazards. The use of sensor technology can also increase compliance with HACCP regulations, improving overall food safety. In the future, we will see more advanced and innovative sensor technology to ensure food safety and compliance with HACCP guidelines.