A Remote Temp Monitoring System

For Cold Chain

Real-time Monitoring | Instant Alerts | Auto Data Collection

- Background -

Whether you’re a cold-chain transportation business owner, quality assurance manager or logistics personnel, making sure the safety of temperature- sensitive products during shipping is the big deal. In other words, you need to do a good job in temperature monitoring in cold chain management.

- Challenge -

Real-time data (temperature, position, GPS trakcing) matters in the cold chain transportation. It should be maintained within a certain range to ensure the quality and safety of the products as well as the vehicle. Factors like weather, temperature, humidity, vehicle condition, etc., can all affect the insulation and preservation effect of products and the delivery.

Temperature Fluctuation

Maintaining a consistent temperature throughout the journey is crucial to ensure product quality and safety. However, temperature fluctuations may occur due to factors like:

- The refrigeration unit is turned off without pre-cooling.

- No multi-channel temperature monitoring in place.

- Mis-handling, and equipment malfunction.

Lack of Real-time Route Tracking

The absence of route (e.g.GPS) tracking functionality will bring various transportation risks and management inconveniences, restricting real-time monitoring and safeguarding of goods. Additionally, it also impacts the safety and efficiency of the transportation process.

Lack of Instant Alert

it may be difficult to know whether there has been any temperature deviation, which is tend to cause the potential asset loss

- Solution -

MOCREO offers 24/7 automated monitoring for better cold chain management, ensuring the protection of temperature-sensitive inventories and route tracking. Equipped with wireless sensors, it collects temperature data and detects abnormalities.

In case of any issues, you and your team will receive alert notifications via Phone call, email, App notification, and local buzzer, avoiding any negative impact on your goods. Quick ROI is guaranteed as MOCREO provides actionable insights and time-stamped data for compliance audits.

24/7 real-time monitoring

Real-time monitoring allows you to directly see the current device status, including parameter values, temperature, and humidity levels. You can also track the vehicle positions in real-time, monitor driving routes, and record historical trajectory data for subsequent analysis.

4 optional instant alerts

Push notifications, emails, or Phone call, device beeps will prompt driver or management staff to take action if temperature goes above or below set limits. Ensure the whole deliverying process safety and efficiency.

Local monitoring

The MOCREO Local Monitor located in the driver’s cabin is equipped with multiple wireless temperature and humidity sensors distributed at different locations within the vehicle compartment.

Drivers can promptly detect anomalies and address them in a timely manner to prevent losses.

GPS tracking

GPS/base station high-precision positioning with real-time updates, map visualization monitoring, timely reporting of on-the-road anomalies (such as temperature exceedance, speeding, parking, etc.).

Data storage & export

Historical data export of each sensor ease staff on manual data checking, logging for analysis.

Multiple accessment

Users can log in at different devices to view the dashboard for real-time environment status checking.

- Benefits -

Improve product quality and safety

It can ensure that the temperature is controlled within a safe range and prevent temperature-sensitive product corruption, deterioration or failure.

Comply with regulatory requirements

With proper temp record-keeping, certain industries, like food and medical, can ensure compliance and avoid fines.

Reduce operating costs

Through real-time monitoring and automatic alarms, this assists management personnel in constantly monitoring the transportation status of goods and adjusting plans promptly to address any unforeseen circumstances.

Improve efficiency

automatic temp monitoring and information recording realize the timely provision of data without manual participation.

Improve customer satisfaction

maintaining product quality, safety and effectively solve problems can enhance customer satisfaction and win customer trust.

- Details -

The MOCREO cold chain management IoT solution is the system for monitoring environmental conditions remotely.

It has wireless sensors, a gateway for transmitting data, and a MOCREO platform for monitoring.

The system can send notifications, emails, and alarms if there is any abnormal condition. The solution is easy to install and can be scaled easily for large deployment.

With the intelligent measurement and control system, the remote monitoring terminals (including various environmental sensors and industrial gateway wireless communication terminal) are installed at each collection and monitoring point as a distributed control node station. The main equipment includes low temperature sensor, temperature and humidity sensor, infrared detector, door and window sensor, power failure alarm, dense fog sensor, flood sensor, etc.

- Long battery life

- Easy to scale

- Reliable, proven technology

Based on cloud servers (AWS, Azure, Google Cloud) and private deployments with advanced data center hosting. You may choose the cloud service solution, or if you prefer private deployment, you may also choose our local server solution. Depending on project needs. The main difference is whether you want to store your data on a cloud server or on site.

Data storage and analysis provides more intelligent insights and accurate drug temperature data for pharmacy/hospital operation and maintenance teams. Big data and cloud computing make automatic management possible.

- Secure and reliable encryption

- Cloud/On-Premise-based big data statistics and analysis

- Accessible around the clock from anywhere

It provides real-time insight into equipment temperature, which allows real-time visualization of data, and timely out-of-standard event detection.

The personnel on duty can receive alerts in time through mobile phones, so as to intervene earlier.

- Easy to set up and use

- Alert threshold customization

- Clear management of individual environmental parameters of pharmaceutical equipment

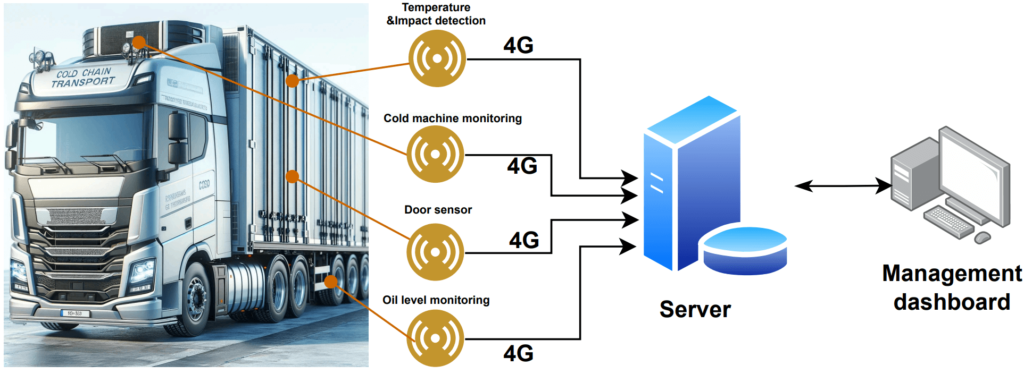

4G Solution

MOCREO offers a comprehensive solution that combines a 4G module with features like temperature monitoring, and GPS tracking. Using wireless sensors, the system gathers data on temperature, location, and routes while actively identifying any irregularities.

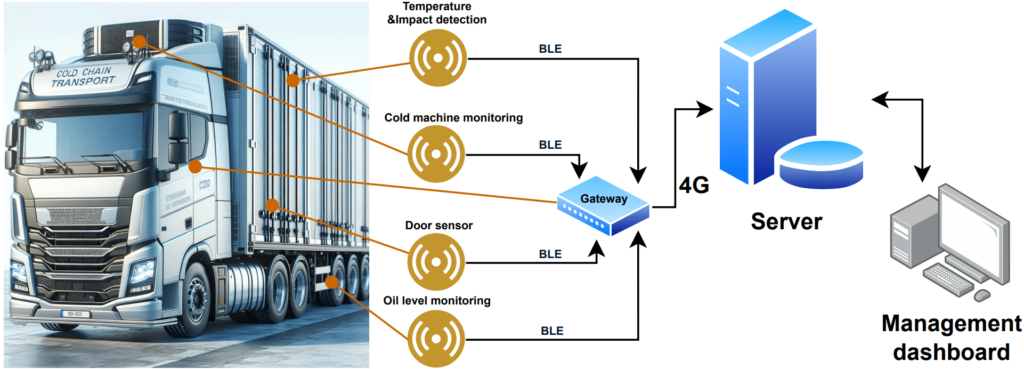

Gateway Solution

The H5 Lite Gateway is installed in the driver’s cabin, with multiple wireless temperature and humidity sensors distributed at various locations within the vehicle compartment. The sensors include temperature, temperature-humidity, door magnetic, and acceleration (impact detection) types.

H5-Lite Gateway

The H5-Lite Gateway is MOCREO’s newest IoT Hub with a display, bridging sensors and servers. With the LCD screen, drive can quickly check out the real-time data (e.g. temperature, humidity), browse through historical graphs

4G All-In One Sensor

Model: ST-4G

Function: Integrates a 4G module with functions such as temperature and humidity monitoring, location tracking, and GPS tracking.

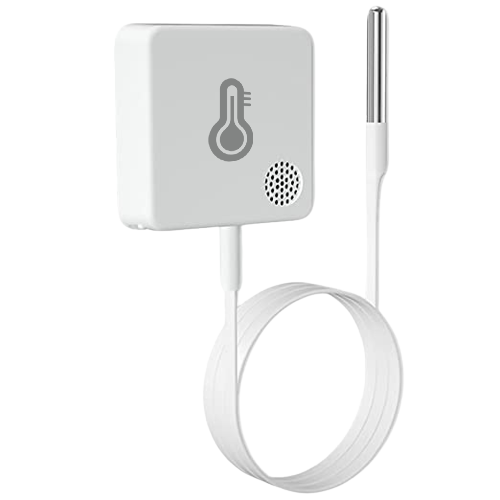

Low temperature Sensor

Model: ST5

Function: To monitor the low temperature of refrigeration equipment, cold storage, etc. Historical data on the temperature can be recorded

Temp &Humidity Sensor

Model: ST6

Function: To monitor the temperature and humidity. Historical data can be recorded.

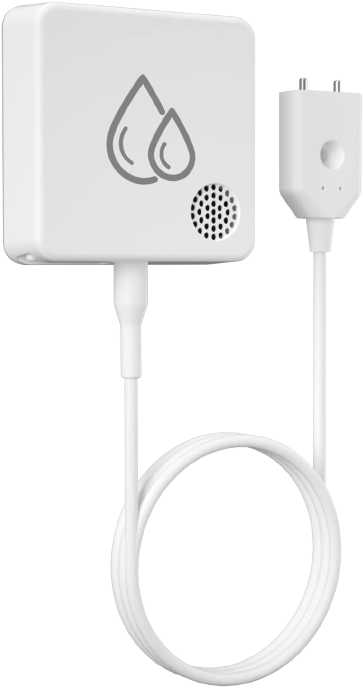

Water leak Sensor

Model: SW2

Function: To detect whether there is water on the ground or to prevent medical products get moldy caused by water leakage in pharmacies

Door and window Sensor

Model: SD1

Function: Records the log of when the freezer door was open. Automate the workflow and save the labor

PIR Sensor

Model: PIR

Function: To detect the presence of people in the area. Analyze the space utilization and presence log.

- Why MOCREO -

Stable system architecture

Our solution provides access and management capabilities for a large number of devices, connects your IoT devices to the cloud platform, supports device data collection on the cloud and issues commands to devices for remote control, and helps you quickly build IoT security monitoring solutions according to different application scenarios.

That is, the perception layer and the network layer in IoT technology.

All kinds of sensors need two conditions to access to the loT platform:

- BLE/ZigBee/Wi-Fi/Lora/ and other communication methods

- Intelligent gateways connection and transmission

By doing so, it could make sure the devices transfer the data stably as well as consumes the low energy during the operation.

Of course, through 4G/5G/LTE-M/Ethernet and other networks, it can access the IoT platform, and use the MQTT protocol to report business data to the platform, and the platform can also issue control commands to devices.

That is, the platform layer in IoT technology.

loT platform take the bridge between devices connection and practical exercises.

It carries the abstract business logic and standardized core data model, which achieves rapid access to devices and provide powerful modularization capabilities, thereby supporting the various needs in industry application scenarios.

That is, the application layer in the IoT technology can quickly build functional modules that meet the needs of the industry by calling the API interface provided by the IoT platform.

Low operating costs

The sensor operates with low power consumption and has a battery life of more than 2 years (8 Seconds an update). That means you needn’t charge the devices or change batteries frequently. A gateway can manage multiple devices to achieve an N+1 effect.

At the same time, you also needn’t train professionals to operate devices. Setup in minutes and easy to use.

Easily scalable deployment

In the MOCREO solution, a single account manages the sensors that are installed at the multiple locations. To add one more sensor, you just need to place the sensor in the expected position and activate it within mins. To monitor another one location, you just deploy one more gateway.

- What Our Clients Said -

It keeps an eye on our temperature-sensitive medical resources

as well as frees us from troublesomely manual recording,

improving the working efficiency.

I’m happy with the products.

The freshness of beef is the big deal.

Once I lost 20 pounds of beef

because one fridge stopped cooling and I didn't know it for 3 or 4 days.

Now, with MOCREO sensors, I can now monitor my freezer remotely

and have peace of mind knowing that my beef is safe.

We have a sensor in each deep freezer to monitor the temperature.

We lost a lot of meat after the door wasn’t shut well.

This is an excellent price for a monitoring system

and it has been working very well for us.

- We Serve for -

Individual & Organization

MOCREO automated monitoring solution peace of mind. Keep an eye on your medical resources. You could click here to try one sample out.

Reseller

We are glad that you could become our partner of the MOCREO family. Lets bring MOCREO Solution to your local market, we help you to succeed!

OEM / ODM Service

With professional knowledge and comprehensive after-sales service, we ensure the successful implementation of customer business projects and help deliver products to the market on time. You have ideas, we help you realize them!

- Future -

Temperature monitoring has a promising impact on the future of cold chain management. With real-time tracking of temperatures, cold chain stakeholders can ensure that goods are stored at optimal temperatures, thereby reducing spoilage and maintaining product quality.

Additionally, the instant alert allows people to forecast the potential risks and take action in time, leading to optimize the cold chain management and reduced waste.

As the demand for high-quality products with longer shelf lives continues to rise, temperature monitoring is poised to become an even more essential component of cold chain management in the future.

- Contact Us -