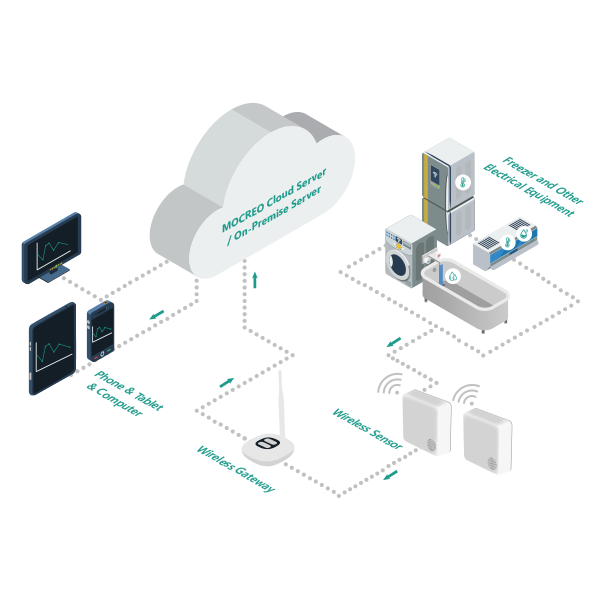

Remote Monitor & Accurate data

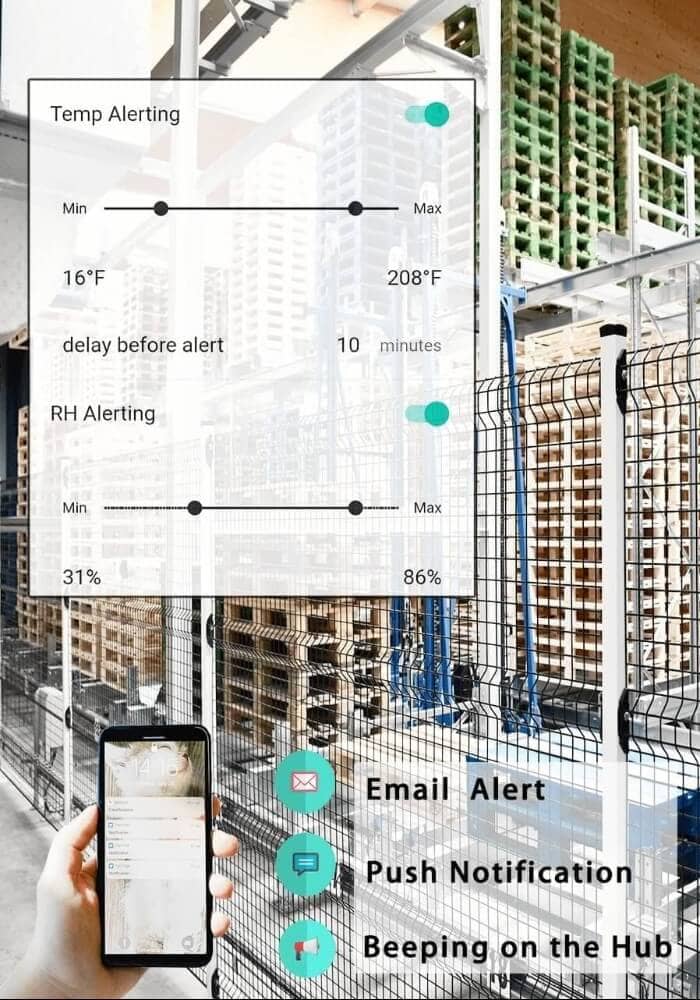

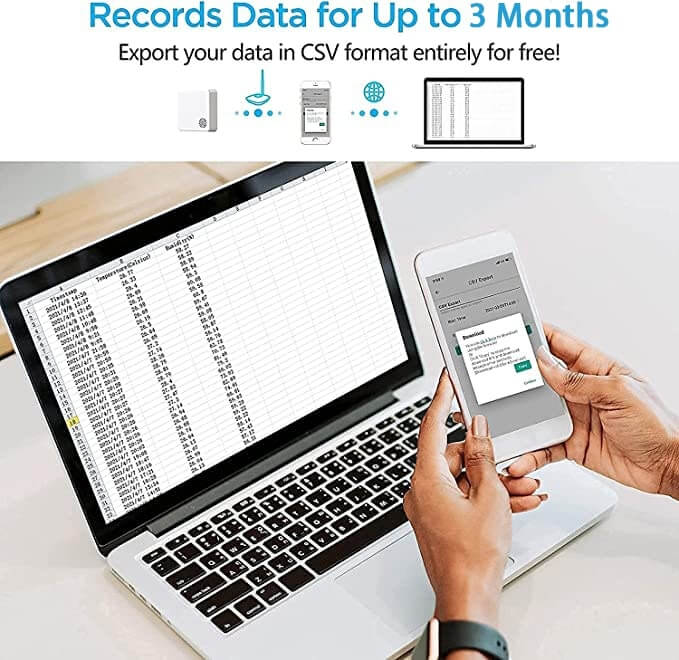

Build-in the Swiss-Made Sensor chip (SHT30), MOCREO Sensor provides you with the accurate value. Administrators can always know temperature and humidity conditions anywhere at any time. They don’t need to be in the sites to read the conditions.

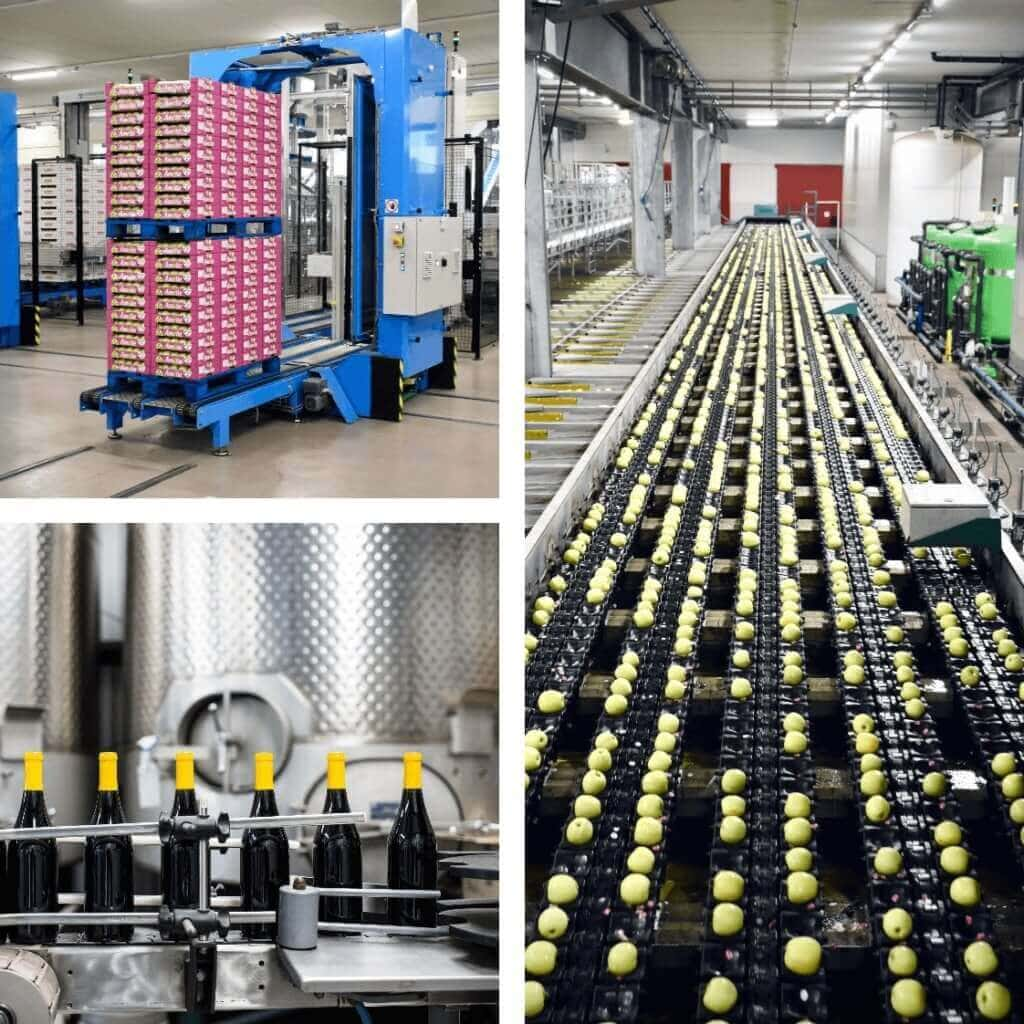

That means you can remotely monitor the temperature range in the appropriate zone 24/7 to make sure ingredients store at a safe temperature, thereby protecting from the bacteria growth. Moreover, it is contribute to maintaining a optimal temperature for food process.

Meanwhile, the accurate data can assist administrators to make regular inspection for temperature conditions. That can guide you to make manual adjustment for optimal temperature, preserving the inventories well while saving the energy consumption of refrigerator and freezer.