Background

IoT is a transformative field that is changing the world, with industries across the board harnessing IoT technology to improve efficiency and profits.

IoT facilitates the exchange of data among interconnected objects, utilizing sensors and actuators to collect and analyze environmental data. Research indicates that the application of IoT technology can reduce inventory errors by up to 30%, lower operational costs, and enhance workflow efficiency.

Particularly in the realm of warehouse management, the revolution brought forth by IoT holds significant significance, as many tasks can be automated through IoT devices, thereby promoting smoother and more efficient warehouse operations.

Challenge

In our perception, traditional warehouses are confronted with numerous challenges such as high labor costs, low efficiency, insufficient real-time monitoring, difficulties in security management, and improper warehouse layout.

However, in today’s context, the IoT plays a vital role in warehouse monitoring systems. IoT-enabled smart warehouses are centered around automation and intelligence, utilizing IoT technology to achieve real-time monitoring and data analysis of goods, remote access, operations, and security and risk management functionalities.

As a result, managers can have constant awareness of the warehouse’s status, optimize its layout, enhance security, and ultimately achieve a higher level of warehouse operations.

Solution

The IoT connects physical objects to the internet, enabling them to communicate with each other through on/off switches.In various industries, including warehousing, IoT technology is employed to facilitate the collection and exchange of data across multiple devices within their workflow. It offers the convenience of unifying all devices under a single, consistent control through internet connectivity.

Real-time Monitoring&Data Collection

IoT enables sensor devices in warehouses to monitor temperature and humidity levels in real-time, ensuring optimal conditions for stored items. If there’s a deviation from the set range, the system triggers alerts or notifies administrators, enabling timely action to prevent item damage.

Goods Tracking&Management

By attaching positioning tags to goods, the warehouse management system can track their location and status within the warehouse. IoT technology enables real-time monitoring of goods, enhancing the efficiency and accuracy of warehouse logistics.

Security Monitoring&Alerting

IoT technology enables security monitoring in warehouses, including the use of cameras, PIR sensors, and other devices for real-time surveillance. Through image analysis and anomaly detection algorithms, IoT systems can automatically identify and alert for any abnormal events.

Equipment Management&Maintenance

IoT connects warehouse equipment and facilities for real-time monitoring of their status, including temperature and lighting. It quickly alerts and notifies personnel when there are malfunctions or anomalies for prompt maintenance and repairs.

Energy Efficiency&Resource Optimization

IoT optimizes energy usage in warehouses by monitoring lighting, air conditioning, and ventilation systems in real-time. This helps conserve energy and reduce emissions. Additionally, data analysis and predictive modeling improve warehouse layout and storage efficiency.

Efficiency&Quality Management

IoT provides real-time data and analysis for warehouse managers to make better decisions. By analyzing goods flow and storage data, warehouse layout and access strategies can be optimized, improving efficiency and quality control.

IoT Devices

- Remote monitoring: Admins can monitor temperature and humidity remotely in real time.

- Specific condition tracking: Sensors track temperature and humidity in storage areas or on goods’ packaging.

- Alert system: Alerts are sent to managers if temperature or humidity deviates from the set range to protect sensitive cargo and equipment.

- Human activity detection: PIR sensors detect human activity and presence in the warehouse.

- Accurate personnel tracking: Warehouse managers can accurately track and manage personnel within the facility.

- Alert system: Alerts are sent when there is inactivity or unexpected conditions in the monitored areas.

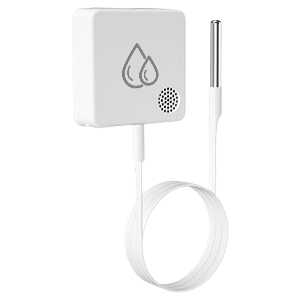

- Leak detection: SW2 monitors and alerts for leaks from pipes, sinks, and water tanks in warehouses.

- Quick damage detection: Strategic installation allows for rapid detection and notification of damage or leakage.

- Prediction of rising water levels: SW2 predicts and alerts about potential water level increases to prevent natural disasters.

- Real-time updates: Warehouse door and window sensors provide real-time updates on their status.

- Monitoring capabilities: The sensors monitor openings, closures, and damages to enhance security.

- Alarm system: Unauthorized access or damage triggers alarms, promptly notifying managers or security personnel.

- Device connectivity: The IoT Hub connects and manages warehouse sensor devices.

- Data collection and buffering: It collects and buffers data for reliable transmission and storage.

- Real-time monitoring: The IoT Hub enables real-time monitoring of connected IoT devices in the warehouse.

- Energy management: IoT smart sockets in warehouse management enable efficient energy management.

- Remote control: The smart sockets can be controlled remotely, providing convenience and flexibility.

- Data analysis: The sockets provide data analysis capabilities, enabling insights for further efficiency improvements and maintenance optimization.

- Real-time vibration detection: The sensor detects vibrations of warehouse goods in real-time.

- Alarms and notifications: It sends alarms to the manager in case of accidents or abnormal vibrations, ensuring prompt action and preventing damage.

- Goods’ safety: The sensor ensures the safety of warehouse goods by monitoring vibrations.

- Equipment failure prediction: The sensor predicts equipment failures and damages based on the analyzed vibration patterns, enabling proactive maintenance and reducing downtime.

- Indoor positioning: The BLE Beacon enables accurate indoor positioning and navigation.

- Accurate location information: It provides precise location information for personnel, equipment, or items in the warehouse.

- Item loss prevention: The Beacon helps reduce item loss by ensuring accurate tracking and monitoring.

- Improved operational efficiency: By providing accurate location information, the Beacon enhances operational efficiency in the warehouse.

WHY CHOOSE MOCREO ?

Benefits For Warehouse Managers

Deploying IoT devices can greatly enhance operational efficiency. Imagine being an inventory control manager, warehouse supervisor, or logistics director who seeks relief from repetitive manual data recording and operational checks. In such scenarios, MOCREO presents the IoT Warehouse Monitoring System as your ideal solution.

- Decreased operating costs

- Possibility of real-time monitoring

- Reduce human resource costs

- Automated facility maintenance

- More accurate analysis and forecasts

- Reduced risks and increased safety for workers

- More informed decisions on supply chain processes

Future

In the present day, smart warehouses leverage an assortment of IoT devices for automating their operations and enhancing productivity. By integrating contemporary solutions, businesses can streamline their operations on a broader scale.

The continuous advancement of technology has provided numerous incentives for automating warehouse setups, including enhanced precision, improved efficiency, round-the-clock operations, and cost reduction through the adoption of IoT technology. Various industries have already embraced warehouse automation to a certain extent, and this trend is anticipated to persist as technology continues to evolve in the future.