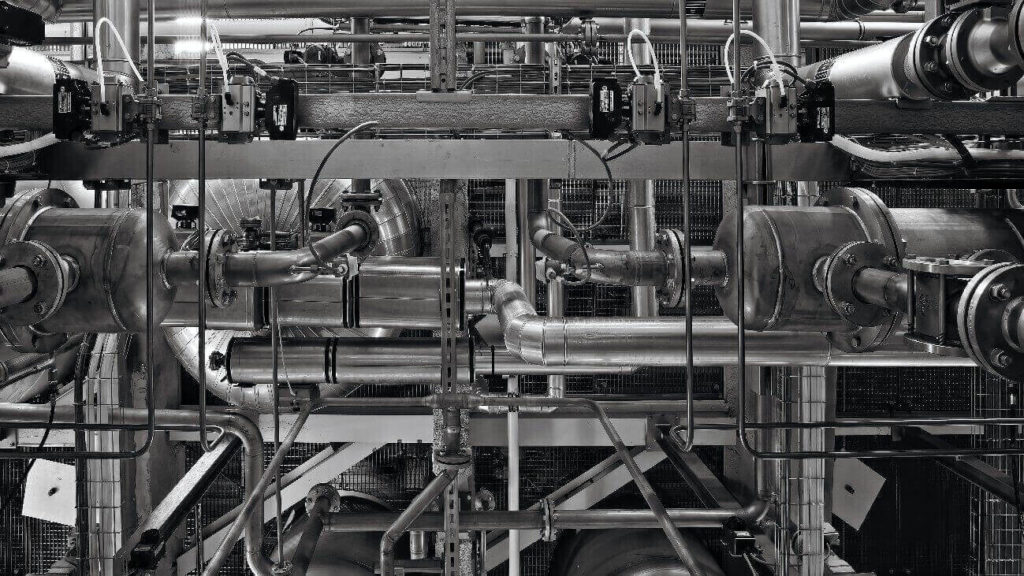

IoT Solutions For Cold Chain

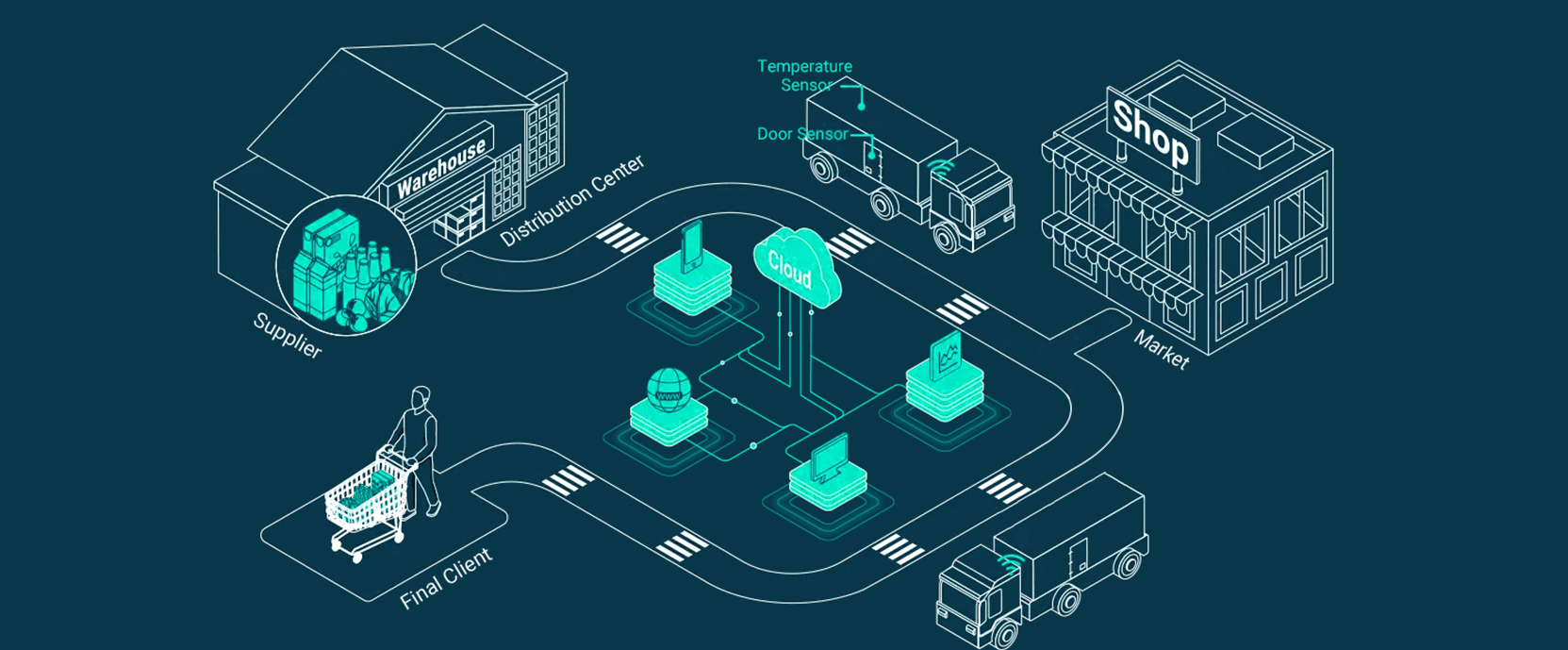

Our IoT-based cold chain solutions cater to your specific logistics requirements. Whether it’s monitoring the transportation of goods from farms to supermarkets or ensuring the integrity of temperature-sensitive products, MOCREO leverage IoT technology to offer comprehensive tracking capabilities.

The significance of cold chain technology has grown exponentially due to the increasing demand for refrigerated storage and transport capacities. This heightened need has generated a corresponding demand for high-quality fresh products. Additionally, the medical industry heavily relies on cold chain IoT Technology to maintain the integrity of pharmaceuticals, as malfunctions can lead to the spoilage of over 20% of all drugs produced. Furthermore, the staggering amount of food wastage every year emphasizes the crucial role of cold chain solutions in preserving perishable items. With our MOCREO cold chain solutions, you can effectively address these pressing issues and optimize your logistical operations.